Component Solutions

Hemro Group’s invisible global reach.

We provide burrs and other grinder components to the largest hotels, coffee and restaurant chains, and commercial and domestic superautomatic espresso machine manufacturers in the world.

The Global Leader

Wherever grinding happens, Hemro is there.

As the industry-leading manufacturer of coffee grinding components, Hemro is trusted by thousands of brands that need reliable precision and consistency. We’re honored to participate in creating millions of quality coffee moments each day through our Component Solutions partners.

Our Burrs

At Hemro Group, we believe in the value of flat steel burrs and reflect this in our four international brands Mahlkönig, Ditting, Anfim, and HeyCafé. We are the global leader in flat steel burr production and support our brands and the industry through our state-of-the-art burr production in Hamburg, Germany.

Flat steel burrs are one of the most common burr types used in coffee grinders. They consist of two flat discs with sharp teeth arranged in specific patterns and facing each other. The burrs share a virtual axis of rotation, whereby one of the burrs is stationary, and the other burr rotates to draw coffee beans between both sets of teeth. The beans are crushed and ground into small particles as they pass through the burrs. The shape and size of the burrs and the distance between them affect the grind size and consistency. Flat steel burrs are known for producing a uniform and consistent grind, making them popular within communities of professional baristas and coffee enthusiasts.

At Hemro, we believe in “special steel” burrs with a higher carbon content to keep the burr’s performance over its lifetime. Our burrs undergo an industry-leading refinement process, and all tool steel undergoes the process below*.

- Cutting: steel rods/bars made from special steel are cut into discs of equal width

- Annealing: the discs then undergo heat treatment to eliminate internal material stresses to allow for easier machining and to prevent post-hardening deformation

- Machining: after annealing, the discs are precision machined to form the “burr” geometry

- Hardening: the burrs are then hardened, which is key to increasing lifetime resilience

- Blasting and other deburring: our burrs are blasted or deburred to prevent settling behavior or shard and metal pieces migrating into coffee grinds

- Regulatory conformity: As a final step, our burrs undergo a material migration test for food safety and are listed in each grinder’s certification report

The crucial perfect match between the motor and the burr set is not ensured when replacing your burrs with imitation or non-Hemro burrs. The burr replacement with unoriginal burrs impacts performance, lifetime, liability and safety as well as warranty.

*Our cast steel burrs undergo a similar process.

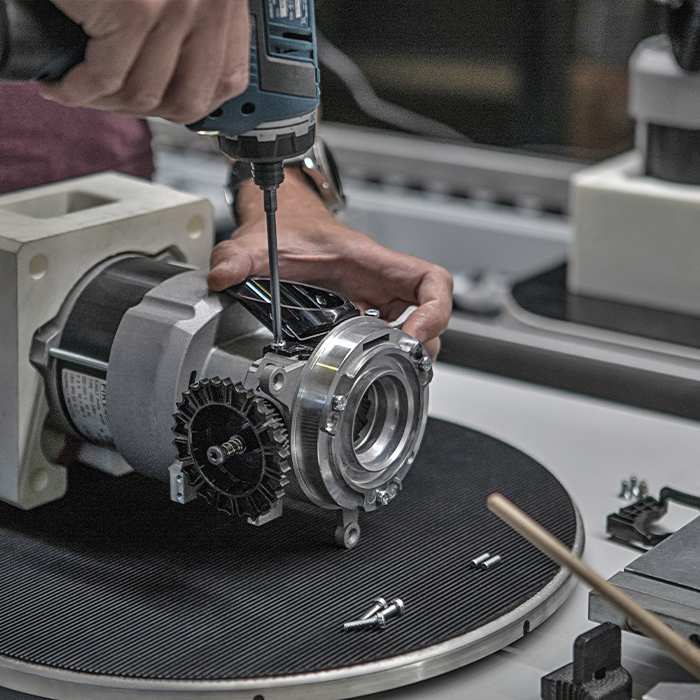

Our Built-In Grinders for Professional & Super Professional Use

For decades, our customers and partners have trusted us with the heart of their coffee-grinding process for professional and super-professional applications. Our built-in grinders in these categories typically cover vending machines, fully automatic machines, and standalone grinders. Our built-in grinders play a decisive role when it comes to quality in the cup, and we pride ourselves in supplying renowned brands with a great array of options to fit each's best need.

Our built-in grinders are built with flexibility and modularity in mind as well as a wide range of taste options (such as Turkish, espresso, filter, and more). Modularity allows for installation in virtually any type of machine, whereas flexibility means that we understand specific needs and can further optimize for every application.

The level of innovation within this category is continuously evolving and this means we strive to bring the latest and best technology and innovations to fulfill modern demands including sensors and actuators that allow for automation, telemetry, and connectivity.

At Hemro, quality is key. Our built-in coffee grinders are designed to meet the highest standard in the industry. Let us help you create the perfect cup of coffee with our professional and super-professional built-in coffee grinders. Please reach out to our Components Solutions sales team so we can help you address your needs.

Our Built-In Grinders for Domestic Use

In addition to built-in grinders for professional and super professional use we also supply many global fully automatic home coffee machine manufacturers with built-in grinders for domestic use.

Built-in grinders for domestic use benefit from all the design know-how of our professional and super-professional applications to ensure that quality in the cup remains a key objective. The main differentiation in this category is that our built-in grinders are designed for lower-duty cycles which are typical for home use. Our ability to enable a broad taste spectrum, modularity and flexibility, low noise, and more, remain key factors that differentiate us in the market.

If you have applications for fully automatic machines or even standalone grinding solutions for home use, please reach out to our Components Solutions sales team so we can help you address your needs.

Our Brewing Groups

For a small range of applications, we also offer coffee brewing unit modules that are perfectly integrated with our built-in grinders. For more information, please reach out to our Components Solutions sales team.

Let’s Partner

Reach out to learn about our grinding technology, component capabilities, and partnership options.